The careful inspection and monitoring of frying oil in commercial kitchens, for example in (fast-food) restaurants or food retailers, plays a key role in ensuring the high quality of the food prepared. Guests and customers are not only entitled to perfectly prepared food. On the contrary, the fried food is often the centre piece on the plate.

Whether schnitzel, french fries or chicken: These are often the dish’s main ingredient that define a meal and, due to the expense or a lack of equipment, that are rarely prepared in the kitchen at home or preferably eaten out. It is therefore important to ensure a positive taste experience. If this is not the case, it is not only the guest's anticipation that will be disappointed. Rather, all efforts for hospitality in terms of ambience and service will be in vain.

This is why human sensory perception plays a role as a quality criterion that can only be measured to a limited extent using physical parameters. Two indicators commonly used in the industry and accepted by the regulatory authorities are the FFA value and the TPM value. What both have in common is that they can provide qualified statements on the quality of the frying oil used. However, they measure different chemical properties.

FFA and TPM measure different aspects of oil composition

The term FFA stands for Free Fatty Acid (value). The value indicates the percentage of free fatty acids in fats and oils. Free fatty acids are a measure of the change in a fat at room temperature through exposure to ambient oxygen, which is responsible for a rancid flavour, or as a result of hydrolysis. This can be triggered by various factors such as heat, light, water and enzymatic activity. The FFA value is appropriate to determine the ageing of unused, i.e. unheated fat, via the free fatty acid content.

Free fatty acids are produced by the hydrolysis of triglycerides, the main components of fats and oils.

There are countries in which free fatty acids are used as an official method for determining the ageing of frying oil. The theoretical idea here is that the FFA value, by indicating the amount of free fatty acids in the frying oil, gives an indication that the oil used has aged and reached the limits of its useful life. From a food chemistry point of view, however, this is only true to a limited extent, as the fatty acid content constantly changes during the frying process. This means that no reproducible measured value can be guaranteed. Measuring the free fatty acids is viable if the fat has not yet been heated.

The FFA value is also particularly relevant for the long-term storage of food, for example potato chips. The FFA value can be used to draw conclusions about the sensory quality of this product. A high FFA value can lead to undesirable changes in the flavour of the prepared product and is a signal that the oil should be replaced in order to maintain the quality of the food.

In practice, this means that potato chips with an increased FFA value will smell musty over time. An increased FFA value can also indicate poor storage, repeated heating or prolonged use of the frying oil.

In the food industry, especially in the catering industry, the FFA value is regularly monitored to ensure that the frying oil is in an acceptable condition. However, according to current research and the assessment of leading experts in the field of oil analysis, this practice is less suitable for the fresh products mentioned at the beginning, such as french fries or meat.

TPM measurement: Greater food safety thanks to a holistic measurement method

While the FFA value concentrates on free fatty acids, the TPM value is an indicator of the quality of the frying oil. However, it is important to emphasize that FFA and TPM values measure different chemical properties. As the TPM value also takes into account a wider range of compounds that provide information on the degradation and ageing of the oil, the two values can only be compared to a limited extent. While each value has its justification, in practice it depends on the specific conditions, intended use and the fried food itself.

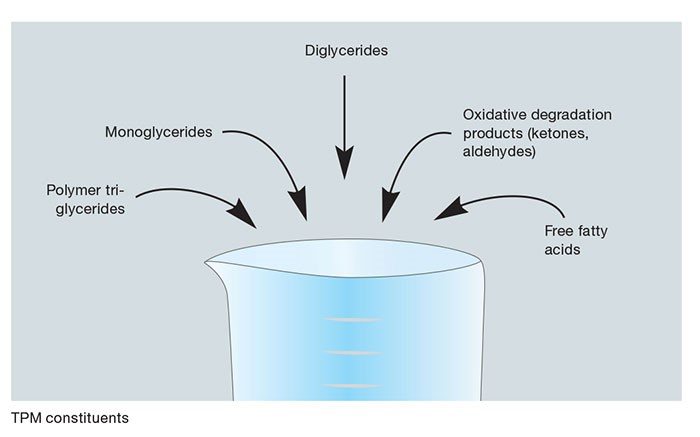

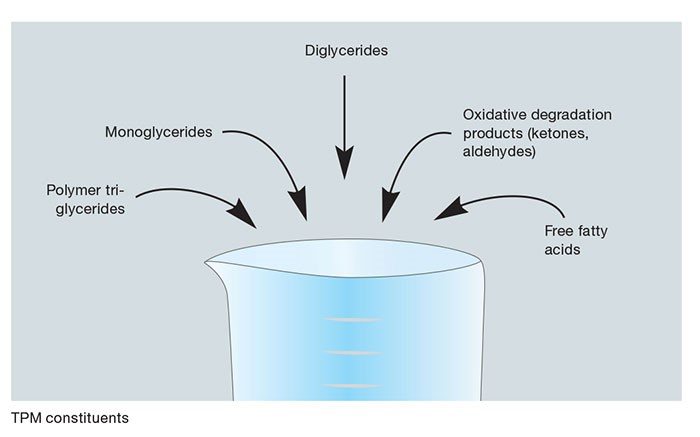

In addition to the free fatty acids mentioned above, various chemical reactions during frying also produce mono- and diglycerides, polymer triglycerides and oxidative degradation products such as aldehydes and ketones. These are summarized as Total Polar Materials (TPM) or Total Polar Compounds (TPC) as a group and used as a measure of the degree of decomposition of the fat.

The TPM value indicates the percentage of these oxidized, polymerized and hydrolyzed compounds and decomposition products in the frying oil. A high TPM value indicates advanced oxidation and ageing of the oil. The measurement of the TPM value is therefore particularly meaningful, as this value indicates the overall condition of the frying oil, while the FFA value specifically measures the amount of free fatty acids produced by hydrolysis. Due to the wider measurement spectrum, a high TPM value can detect potentially harmful compounds in frying oil, which protects the health of consumers.

Optimized sensor technology: TPM measurements ensure the flavour and quality of the fried food

The “Total Polar Materials” affect not only the consistency, taste and appearance of the fat, but also its frying quality. A product which is deep fried in spent oil very quickly forms a dark crust but at the same time sucks in a large quantity of fat. In fats with a high proportion of polar materials, the water can escape more quickly via the fat and the product dries out more quickly. French fries, for example, become hollow inside.

As a result of the rapid loss of water, the steam protection cover also disappears, which means that the fat comes into contact with the surface of the food for a longer period of time. The consequence of this is that more fat permeates into the inside of the product being deep fried, but also that the surface is exposed to a higher temperature for a longer period of time and there is therefore more opportunity for browning.

Intelligent technology for the kitchen: How frying oil measurement works

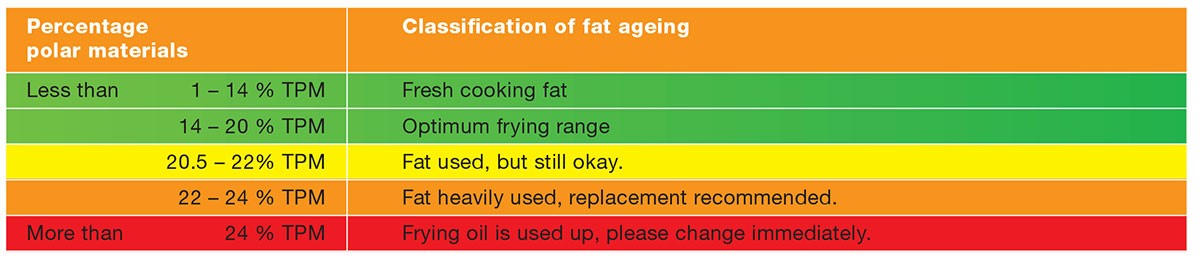

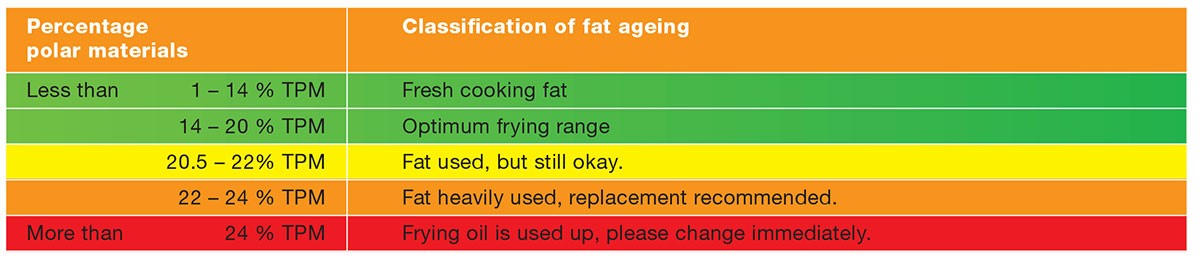

The fat changes over the course of its useful life. While there are no flavours or odours in the fat when it is first used, these develop when it is heated for the first time. Thanks to these aromatic substances, the fat then approaches its optimum frying range. This is where the best result for crispness and taste is achieved. The more often the heating process is repeated, the more the fat decomposes until it finally becomes inedible. This life cycle can be precisely visualized using the TPM measurement. Testo defines the optimum as a TPM value between 14 and 20 percent. This value is determined by the respective national regulations. The maximum can vary between 24 and 30 percent TPM depending on country-specific requirements.

TPM measurements can be carried out using the testo 270. Depending on the measured value, the display lights up green, yellow or red.

The TPM value of fresh fats can vary depending on the type. Palm oil has a higher TPM value at the start than rapeseed oil, for example. This is due to the composition of the fatty acids. However, this does not mean that rapeseed oil is an inferior frying fat. On the contrary: Rapeseed oil has a longer shelf life compared to oils with low starting values.

How regulatory requirements for frying oils can be improved

Many companies find themselves in a dilemma when it comes to frying oil management. In most cases, frying oil measurement has two main purposes: Ensuring quality and ensuring compliance. The two do not necessarily have anything to do with each other. From a scientific perspective, the TPM value is very well suited to ensuring the food safety and sensory quality of freshly fried foods. However, in many countries, for example in Germany, it is common practice for the supervisory authorities to request the FFA value, among other things.

A high FFA value can in fact be a signal that the oil should be changed. However, as already mentioned, the value for fried and immediately served food is not necessarily useful, as the content of fatty acids changes constantly during the frying process, and therefore no reproducible measured value can be guaranteed and the sensory changes only occur with longer storage of the food.

The sensory properties of the frying oil should also be part of quality assurance

In addition, the FFA value cannot provide any direct information about the taste and aroma of the freshly prepared food. The FFA value alone can therefore not cover all aspects of sensory quality. For this reason it is important to replace the oil in good time, regardless of the FFA value. The product being fried also plays an role: Different foods have different effects on the frying oil. Some foods can tend to cause a deterioration of quality more quickly than others.

Taste, smell and texture are decisive for the sensory evaluation of freshly fried food as part of quality assurance. Even with a low FFA value, frying oil can be subject to sensory deterioration after repeated use. This is because: Even if the FFA value is low, the frying oil can be affected by oxidation processes and the formation of by-products, for example through exposure to heat or air. In addition, there are polymer compounds and aromatic compounds that can occur due to chemical reactions during frying, which lead to the formation of aromatic compounds. The food itself can also release undesirable flavours into the frying oil.

Quality, health, economy: Testo recommends TPM measurements

Based on these findings, Testo expects that the measurement of the FFA value will become less and less important for companies and supervisory authorities and that the TPM value will become more relevant due to its wider range of measurement parameters.

A good TPM value ensures that the fried food has a consistent quality and taste. Potentially harmful compounds can be detected and controlled, protecting the health of consumers. There are also economic aspects. By changing the frying oil in good time, the overall service life of the oil can be extended and the amount of product used is reduced. Last but not least, the use of high-quality frying oil also has an impact on customer satisfaction and the image of companies. By using high-quality frying oil, companies can maintain the quality of their food at a high level and thus ensure customer satisfaction and their own good reputation.

Testo South Africa (Pty) Ltd

1 Glen Eagles Office Park

Cnr. Braambos & Monument Rd.

Glen Marais 1619

Kempton Park, South Africa

Contact number : +27 11 380 8060

Email : info@testo.co.za