Food safety and food quality are two of the most important concepts when it comes to food processing and distribution.

Food safety mainly refers to the requirements (including those made by legislators) to protect consumers from any adverse health effects, while the term food quality covers the requirements and definition of the customer.

Product quality is a perceptible customer benefit and awakens the desire to purchase the product again. However, it is difficult to make a clear distinction between the concepts, because various points are to be found in both areas. The term food quality will also often be used below as an umbrella term for food quality and safety.

Food producers and food retailers have the task of protecting consumers from adverse health effects or damage and ensuring the safety of food. The sale of food that is not marketable, of poor quality, or unsafe can result in serious damage to the image of the companies concerned.

According to the 178/2002 basic regulation, "marketability" means that foods are -

- not injurious to health and

- fit for human consumption.

Products that are not deemed to be perfect are for example ones that are not spoiled and are still edible but do not meet the required standard in terms of their appearance, for example, lettuce that has become limp and no longer looks appetizing to the purchaser.

However, food is no longer safe if it is spoiled. This can lead to the consumer feeling unwell or even to adverse health effects. Because the quality and safety of food can be negatively impacted by the wrong temperature, monitoring the temperature of products that require refrigeration is a key component in ensuring the required quality and marketability.

Traceability:

Crucial in the event of a claim.

Foods run through various processing stages on the way from raw products to goods that are ready for sale. This creates a chain from producers to processors and retailers. For example, if spoiled foods get onto supermarket shelves, the issue of responsibility arises: who is liable in the event of a claim? According to the principle of due diligence, all food businesses bear the responsibility for meeting the requirements of the food safety laws themselves.

One crucial legal obligation is the assurance of traceability. This must be guaranteed at every stage of the entire food chain (from the producer to the consumer and vice versa). If refrigeration of the product in production, storage, transport and/or sale is crucial to the quality or safety of the food, it must be provable that the right temperature, and thus compulsory refrigeration, has been adhered to here as well.

Temperature measurements for an unbroken cold chain.

For companies in the food sector, checking the correct temperature all along the cold chain is one of the basic measures for assuring quality and guaranteeing compliance with legal and internal standards. Because temperature fluctuations are often the cause of spoiling or impaired quality when it comes to food.

In the case of foods that cannot be stored at room temperature without potential problems, the cold chain must not be interrupted. Most products pass through many different hands on their way to the end consumer – in transport, temporary storage facilities, and distribution centres. When products are handed over to another logistics service provider or to a distribution centre, the responsibility for food quality and food safety also changes again and again all along the cold chain.

Failure to maintain the cold chain can lead to spoiled food and, as a consequence, can cause harm to the company's image and thus result in lost sales for the company. Temperature control, therefore, serves to ensure the safety and marketability of foods that are subject to the cold chain. In addition to the legal requirements and temperature limit values which are binding during the production, transport, storage, and sale of foods, various temperature terms are used: storage temperature, product temperature, air temperature, core temperature, and surface temperature. What are the differences between these types of temperatures and how significant are they in terms of product quality? Also: what measurement methods are there and which of them are best suited for monitoring food temperature? We would like to examine and clarify these questions in greater detail below.

|

Measuring in rooms: the challenge of stratification

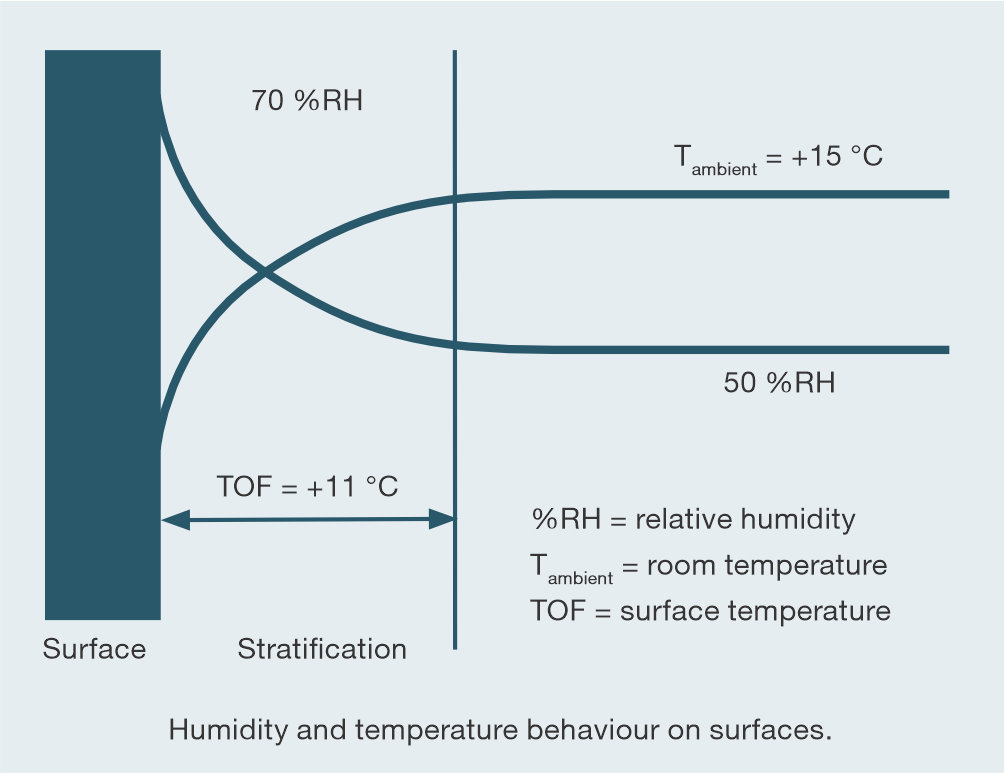

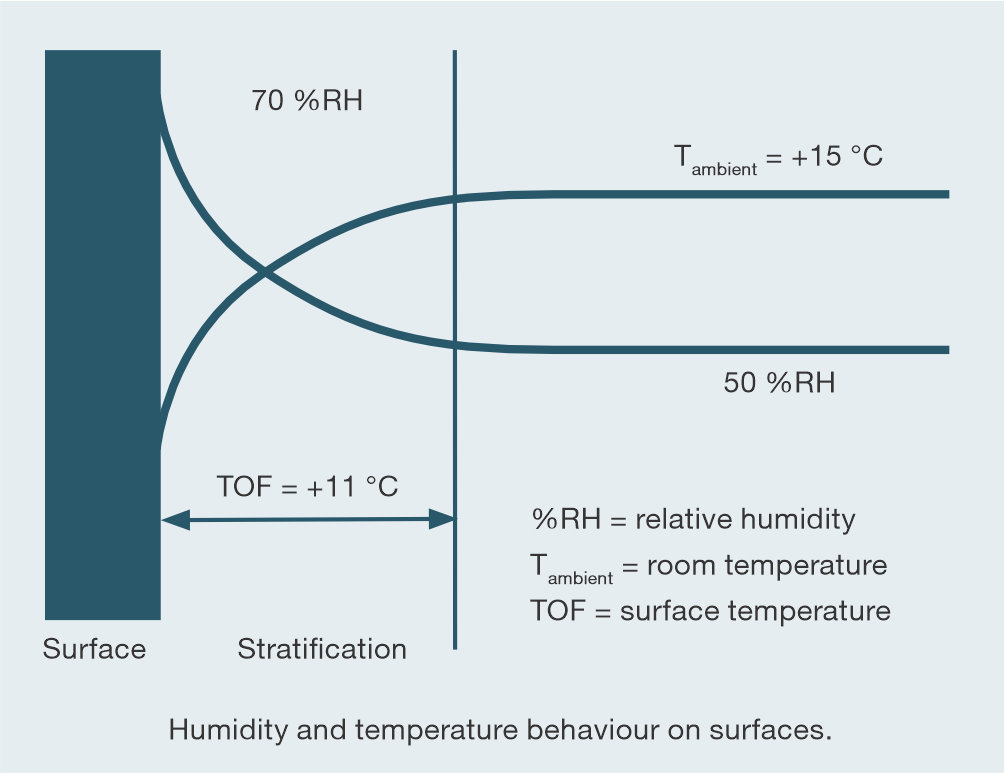

Measurements taken inside a room may be distorted by what is known as stratification around surfaces. The risk of stratification arises if the surface temperature differs a great deal from the air temperature.

To avoid measurement errors of this kind, a minimum distance from surfaces should be adhered to. This minimum distance has been reached when no further changes in the readings occur in spite of the distance being altered. The measuring location for every measurement should therefore be chosen with care and an

appropriate measuring distance adhered to.

|

|

This also applies to conditioned air inlets from heating or refrigerating equipment. This kind of stratification can also occur in stagnant air between the floor and ceiling, for example in large storage rooms. Control measurements should therefore be taken at the points which have been found to be representative of a survey of the indoor climate.

Fixed probes at various locations are common in refrigerated rooms.

|

|

Air and product temperature:

What really is the difference?

Foods requiring refrigeration are cooled in refrigeration facilities such as walk-in freezers by the cold contained in the airflow.

In terms of temperature control, a distinction needs to be made between the following types of temperature: the air temperature indicates how cold the air in the refrigeration facility is. The temperature of the cold air enables us to conclude that the refrigeration facility is achieving the correct cooling capacity.

Although the product temperature is largely determined by the air temperature, the determined air temperature cannot be equated with the product temperature. However, the reaction to fluctuations in the air temperature is dependent on the type of food or packaging or on the condition or degree of processing (pre-cooked, raw, frozen) of the food.

The product temperature of a completely frozen chicken is relatively constant, even when there are considerable fluctuations in the air temperature, whereas the temperature of 100 g of fresh minced meat adjusts significantly more quickly to the change in air temperature. This means that the actual product temperature may differ from the air temperature within the refrigeration facility.

Negative influencing factors (e.g. the radiant heat from the refrigeration unit lighting, frequent door opening or loading errors) cause elevated cooling air temperatures – often undetected by staff. Temperature probes and indicators permanently installed by the manufacturer of the refrigeration unit can still indicate air temperatures within the specified limit values because the temperature probes are placed in the air outlet area (i.e. in the cold areas of the refrigeration facility). It is therefore particularly important to take into account the different temperature zones within a refrigeration facility when taking measurements. If this is not done, the air temperature measured and documented by the installed probes will not be correct.

The product temperature is the temperature of the product. It can be determined either as the surface or core temperature. It is measured on the surface (surface temperature) or in the core (core temperature) of the food. The product temperature is a crucial factor for maintaining the product-specific characteristics until the expiry of the best-before or use-by dates.

Two measuring methods:

Sampling or recording?

In terms of temperature control, we differentiate between two types of monitoring:

1. Spot check measurement

Is carried out with portable (mobile) temperature measuring instruments, which are either pure measuring instruments (which merely display the measurement value), or storage thermometers which save the measured data in internal memory or send it wirelessly to a data storage device.

2. Continuous data recording

Here, a measuring instrument with memory remains with the goods (or in their proximity, e.g. the cold storage room) and records and stores values at regular intervals (measuring intervals). Depending on the type of data logger, the data is either stored in internal memory and read out manually or sent wirelessly to a data storage device.

Portable hand-held measuring instruments:

Which one meets your needs?

| Instruments with interchangeable probes |

Instruments with a folding mechanism |

• Particularly suitable for a variety of different measuring tasks, since probes can be interchanged depending on the measuring task.

• Examples: Measuring the core temperature of meat, checking surface temperature, or determining the quality of cooking oil (%TPM, °C). |

A popular design in which the robust measuring tip is permanently attached to the instrument and can be "folded away" to save space.

• Infrared sensor for non-contact surface temperature measurement and penetration probe for core temperature measurement.

• Examples: Measuring the core temperature of fresh products in refrigerated counters, and surface measurement when inspecting incoming goods. |

|

|

When using hand-held measuring instruments:

How do I measure correctly?

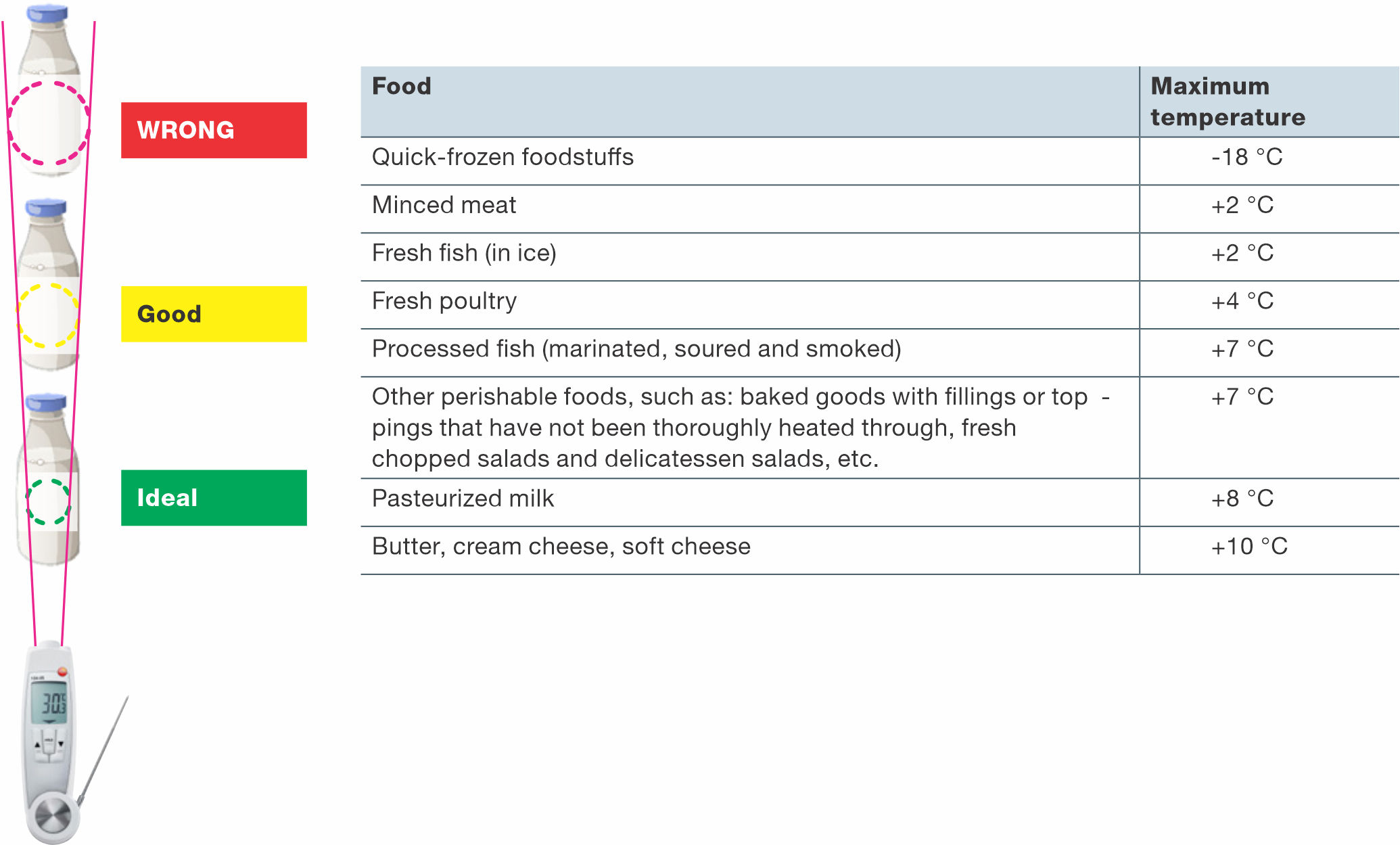

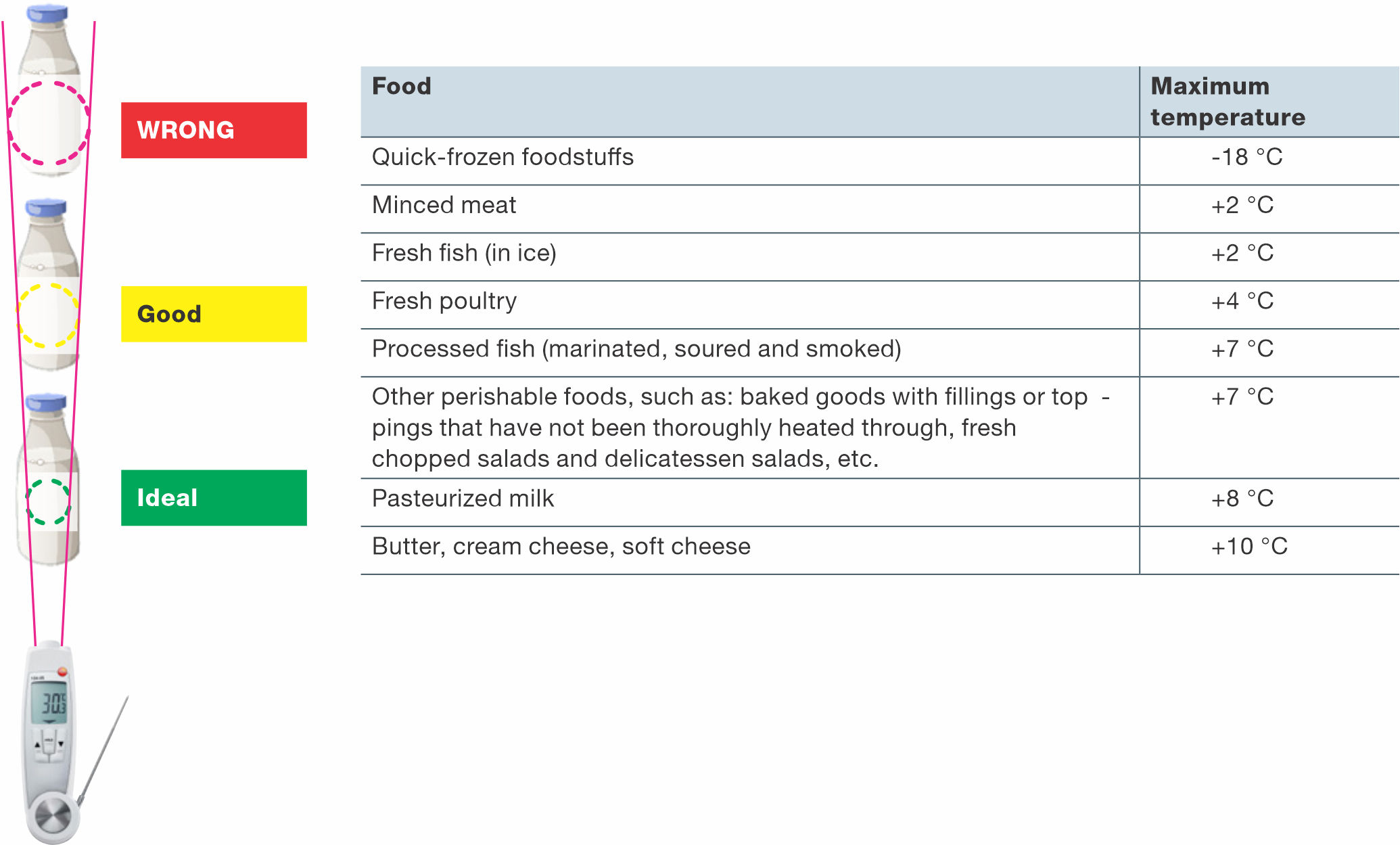

The most accurate measurement is always a core temperature measurement, i.e. a penetration probe measures the temperature inside the chilled product. However, this means damaging the packaging of many products. To avoid this, a three-step procedure has become established in practice:

- First, the surface, e.g. of yoghurt pots, is scanned using an infrared measuring instrument to get a quick overview of the temperature of the products. If the temperature is clearly within the “green range”, the test is finished. For example, the yoghurt pots have a temperature of +5°C (target: max. +8°C).

- Is the temperature of some yoghurt pots above +8 °C? Then a contact probe is inserted between two yoghurt pots and a measurement is taken. This measurement also enables non-destructive temperature checking.

|

|

3. Is the temperature still too high? A final penetration measurement is then carried out on one or more pots. The probe is inserted through the lid into the food and thus measures the correct core temperature. In order to carry out this three-step procedure quickly using one temperature measuring instrument, it is best to use a multi-purpose instrument that has both infrared and penetration probes, e.g. the testo 104-IR. You can find more information at: https://www.testo.com/en-ZA/testo-104-ir/p/0560-1040

|

Non-contact measurement:

What do I need to keep in mind?

There are instruments that measure the temperature without direct contact with the food: infrared measuring instruments. They are suitable for obtaining a rapid overview of the temperature of the products. This so-called non-destructive measurement enables the temperature to be determined without the instrument coming into contact with the product.

The measuring instrument

• Measure with a clean lens. Dirty or fogged lenses (e.g. due to water vapour) can falsify the measurement result.

• Acclimatize the measuring instrument to the ambient temperature. Either store the measuring instrument where it will be used or wait for approx. 15 minutes until the temperature of the measuring instrument has acclimatized to that of the measuring location. If the instrument temperature does not correspond to the ambient temperature, this can falsify the

measurement result.

The measuring surface

• Measure clean surfaces. Dirt, dust, or hoarfrost can falsify the measurement result.

• Measure packaged food at points where the product and packaging are in direct contact. Air pockets can falsify the measurement result.

The measuring distance

• The closer the better. This ensures that only the measurement object is measured, and not its surroundings too.

Ideal for continuous recording of measuring values:

Stationary data loggers.

Data loggers are suitable for monitoring cooling and heating equipment. For cold storage and freezer facilities larger than 10 m³, permanent temperature monitoring is mandatory.

Usually, the air temperature is monitored. Testo's data logger portfolio also includes the option of monitoring humidity and door movements (open or closed) as well as simulating the product temperature.

Wherever the primary focus is on food quality (e.g. monitoring beverage refrigerators), the most sensible solution is to monitor the air temperature. If the focus is on food safety, then simulation of the product temperature is appropriate in addition to purely monitoring the air temperature. Here, the core temperature of a food product is derived from the air temperature. This way, there is always certainty about the actual condition of a product, regardless of short-term fluctuations in air temperature.

Humidity monitoring plays a central role, for example, in dry-aging cabinets, and in heat-retaining environments. In addition to these measurement parameters, the monitoring of doors (open or closed) is also extremely useful. Open doors mean that the cooling system works continuously to maintain the temperature level. This results in higher power consumption and consequently higher costs.

Depending on the requirements, an appropriate measuring interval is 15 minutes, for example (e.g. according to EN 12830). But shorter (at least 1 min.) or longer measuring cycles are also possible. When using a radio or WIFI data logger system such as the wireless sensors from Testo, the data is automatically forwarded to a central database (cloud-based) after each measurement. There, both current and historical values can be viewed at any time.

In order to be able to intervene proactively in addition to purely recording measurement data, individual limit values are stored in the system for each individual data logger or measuring point.

When setting the limit values, guidance can be sought on the basis of applicable national guidelines or more stringent internal limit values can be set. If one of these limit values is subsequently violated, an automatic notification is sent to a defined group of recipients. Notifications, e-mails, and SMS can all be used here.

Unlike systems that do not use a data logger, this enables the recipient to intervene immediately to eliminate the cause of the error before the food exceeds critical limits and therefore has to be thrown away.

A monitoring system thus offers the advantages of continuous monitoring without manual interaction (reducing manual work and costs) while ensuring food quality and safety (reducing food waste while saving money). Moreover, continuous monitoring enables the equipment’s cooling settings to be optimized, thus saving resources such as electricity costs. In order to determine the ideal measuring points in the equipment, temperature mapping is recommended in advance in order to identify cold or hot spots.

Important: Data loggers for chilled and frozen food must comply with the EN 12830 standard in the EU.

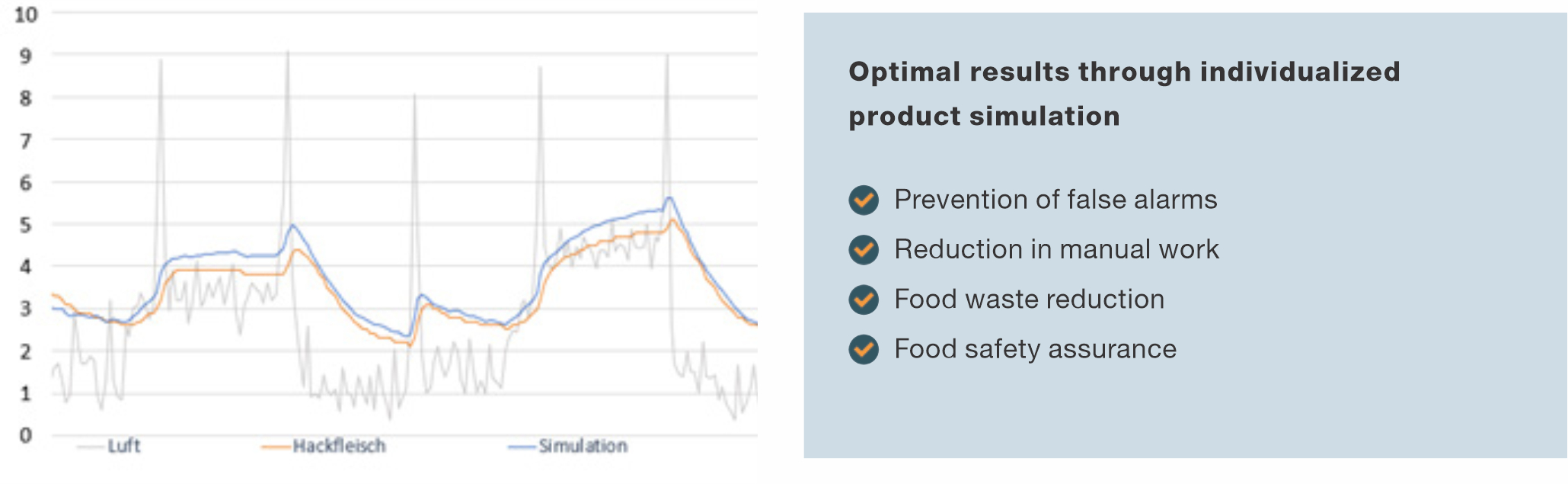

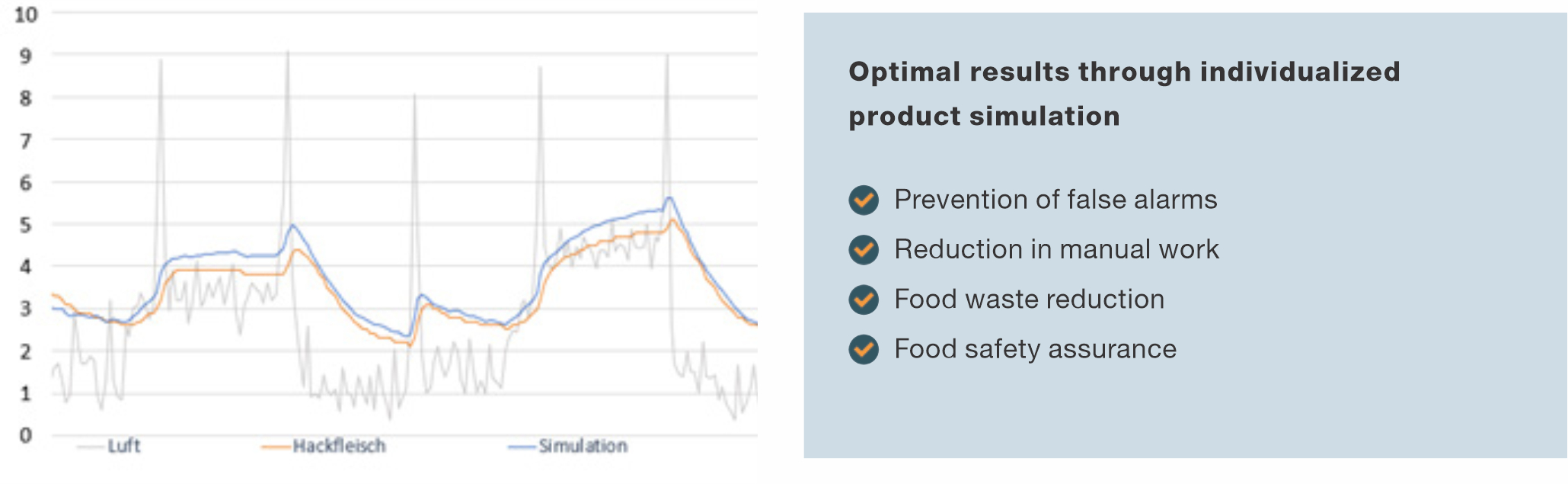

Optimum results through product simulation.

Why simulate products?

In addition to continuous monitoring of the temperature in cold storage and freezer facilities, product simulation is recommended for monitoring the actual core temperature of food. The rationale for this is the fact that the air temperature reacts faster than the temperature of stored food. As a result, avoidable alarms may be triggered and extra manual work required.

Furthermore, there are sometimes significant drops in temperature within refrigeration units, so food in hot or cold spots may be at risk despite non-critical readings. The result: higher costs due to avoidable food waste!

The Wireless Sensor T2 enables software-based product simulation that can be configured according to your individual quality requirements. In order to obtain an optimal result in the product simulation, Testo takes various variables into account. These may include the cooling equipment used, the specific usage behaviour as well as the product and its packaging size, for example. The algorithm developed by Testo achieves a level of accuracy that has also been certified by the NSF.

Optimal results through individualized product simulation

- Prevention of false alarms

- Reduction in manual work

- Food waste reduction

- Food safety assurance

What else you should keep in mind when using measuring instruments?

- Measuring instruments used to determine the temperature of food should be calibrated regularly. In the event of major discrepancies, recalibration is recommended. Calibration means comparing the measuring instrument with a reference instrument which is traceable to a national standard. There are special service providers for this, such as Testo South Africa’s SANAS calibration laboratories.

You can find out more at https://www.testo.com/en-ZA/service/calibrations

- In addition to the directives and regulations for food producers, suppliers and retailers, there are also stipulations for measuring instrument manufacturers which precisely regulate the technical characteristics or minimum requirements for hand-held measuring instruments and data loggers. This is necessary in order to achieve standardized regulations regarding discrepancies in measurements, recording periods, protection against dirt and water, etc. Users should make sure that their instruments comply with the relevant standards (e.g. DIN EN 12830, EN ISO 13485, DIN EN 13486) and that a so-called type test

(approval) has been carried out by the manufacturer.

About Testo

Testo is a world market leader in the field of portable and stationary measurement solutions. The high-tech company employs 3,000 people in 34 subsidiaries around the globe to research, develop, produce, and market its products. Customers all over the world are impressed by the measuring technology expert’s high-precision measuring instruments and innovative solutions for the measurement data management of the future.

Testo products help save time and resources, protect the environment and human health, and improve the quality of goods and services. In the food sector, measuring instruments and monitoring systems from Testo have proven themselves for decades, and belong to the standard equipment of food services, supermarkets, and food producers.

Average annual growth of over ten percent since the company’s foundation in 1957 and a current turnover of over a quarter of a billion euro clearly demonstrate that the Black Forest and high-tech systems are a perfect match. The above-average investments in the future of the company are also a part of Testo’s recipe for success.

Testo invests about a tenth of annual global turnover in research and development. For the food sector, Testo has developed specific solutions which combine precise sensors with intuitively operated software and comprehensive services, tailor-made for the requirements of the respective field.

Find out more at https://www.testo.com/en-ZA/